The Problem

Imagine a simple solution to the age old problem of patching scaffold ties

at exterior plaster

Conventional Scaffold ties and the hazards they create to water

management systems

For years, those of us in the Lath & Plaster industry have dealt with the inconvenience that scaffold ties create to the integrity of the lath and building paper, and the aesthetic look of a plaster patched tie. The problem for Plasterers is the method used by the scaffold erector to attach their scaffold to buildings and the damage to our plaster and water management systems.

Typically, scaffold is erected prior to the installation of any framing and or lath and plaster. Traditionally, the most common type of attachment used by the erector is going to be a push-pull tie; the cheapest and easiest way to erect scaffold. This attachment is usually comprised of #12 wires and a compression post that penetrates our walls to the building structure. However, when the scaffold is dismantled, gaping holes are left at the penetrations for the plasterer to deal with. Often very little concern or attention is given to the proper paper patching of the removed ties and once covered with plaster the risk is hidden. Many times the location of scaffold ties are in close proximity to floor line expansion joints, and if not properly addressed, are at high risk for moisture intrusion. However, for the Lath & Plaster contractor, the risk of a lawsuit due to moisture intrusion has become a major concern, and they should always be looking for ways to minimize their exposure. In addition, the cost associated with properly patching the holes left by wire ties is usually overlooked when bidding a project, and can have a substantial impact on the bottom line.

Conventional Push-Pull wire tie

Fortunately, the plaster contractor is often in a position to require the scaffold sub to use a specific product for a certain application if we feel it is for the overall success of the project and will reduce our liability for moisture intrusion.

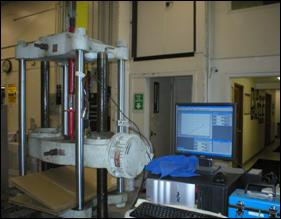

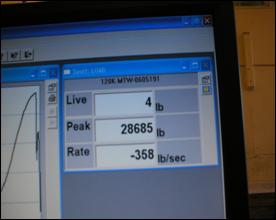

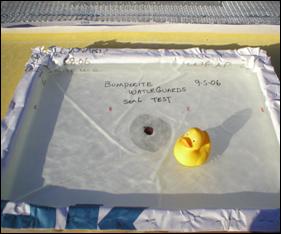

The new Bumperite Waterguards sealable scaffold attachment system has been developed as a cost effective solution to the multiple problems created by conventional wire ties. This Southern California based company has developed a sealable scaffold attachment that can be installed as part of the water management assembly eliminating the need for any paper patching or caulking once installed. The system has been tested at Smith-Emery Laboratories, Inc. located in Los Angeles California, using test method ASTM E331-00 as a water-resistant system providing a higher level of protection.

Not only does the Bumperite Waterguard system eliminate liability due to leaks caused by conventional wire ties, it also enhances the safety of the scaffold through a superior attachment. Bumperite is OSHA compliant and has been pre-engineered and structurally tested.

What more could your insurance carrier ask for?!

The Bumperite System is available for four methods of attachment: wood framing, steel framing, concrete, and welded attachment to steel bent plate. The welded attachment is ideal for tarped or enclosed scaffolds in high wind conditions with a 4500 pound push-pull capacity.

If you have ever been involved in a dispute regarding moisture intrusion, you can appreciate the benefits of a low cost, preventive approach that can save you hundreds of thousands of dollars in the future by avoiding potential pitfalls. The Bumperite Waterguards sealable scaffold attachment has many benefits. Maybe the most important is peace of mind!

Enhance Safety and Eliminate Water Intrusion at Scaffold ties